|

|

|

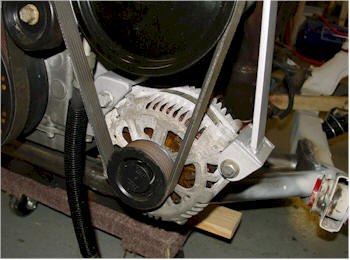

This is the shot from the bottom - up,

it is hard to see, but the only thing coming in contact with the

firewall is the water pump pulley everything else seems to have room

with the exception of the alternator. The alternator sits at

the uppermost part of the driver's side of the engine. The

firewall will have to be cut out there to clear the pulley. |

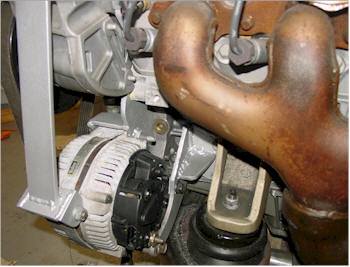

Another shot of how close it is

without modification. |

|

|

|

Rather than cutting the firewall I

personally did not like the alternator sticking up so high on the

engine, since I first saw it. In a Corvette there is no room to mount

it anywhere else. I began doing some research on if a company

made a re-mount kit for an LS1. I came up short everywhere I

looked, and then and I came across Vortech

superchargers. Their kit has a relocate system with the

Supercharger kits. After finally finding some installation

pictures, I found that it just moves it from the Right side to the

left side and only moves the problem and does not fix it. The

AC compressor sits on the passenger side on the lower part of the

engine and on the other side under the Power Steering pump there was

a wide opening, I thought it may be worth the time to see if

the Alternator could be moved there. . |

|

|

|

After about 8 hours of cutting paper

templates and trial and error I cut and made three brackets out of

1/4" steel. Alignment on an accessory is very critical I used

a level and calipers to ensure alignment before welding the brackets

together. What I found was nice was that the front of the block plus

1/4" steel made the alternator flush and aligned with the rest of

the accessories on that belt. There was about a 1/16" gap

(more needed) in the spacing and that was filled with a simple

washer. With the first mounting hold made I was then able to

construct the rest of the brackets. Probably one bracket too

much and we probably did not need to use 1/4" however I was not

about to take any chances. I coated them with aluminum paint

to match the rest of the brackets on the engine and installed them |

|

|

|

You can see here the old and new

alternator location. I will also have to re-locate the power

steering pump reservoir. This is not a big deal since it is

not pressurized I only need to make sure it is above the pump for

gravity to work. |

| |

|

|

|

|

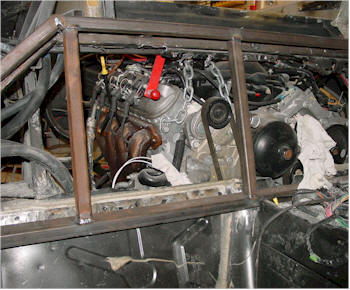

This is the first test fit of the

engine fully bolted in. |

It really looks bad to try and cover

up so we decided to completely gut the back firewall. |

|

|

|

The opened it up providing all the

clearance we needed. |

We started to fabricating the New

firewall support. and framed it so the engine would have plenty of

room. |

|

|

|

On of the first things we noticed was

how much room we had for the water tube that points in the wrong

direction...... We are working out a solution for this but we

did not let it stop us so we moved on. |

Everyday we work on this we get closer

to trying to make it look more and more original. We mounted the

Seatbelt crossmember. |

|

|

|

Test fitted the center console which

will be trimmed down from the top for an original look. |

Here is the engine from the top, and

mounted. |

|

|

|

we had to trim the rear bumper support

to clear the transaxle housing. |

Plenty of ground clearance and

it will be almost covered by the bumper. |

|

|

|

Rear view |

We took the engine out and focused on

the engine bay. It looked like a mess and since we cut out so

much it did not lend itself to any additional structural support. |

|

|

|

Another view of the mess |

Ahhh it looks much better all

the old supports were cut out and removed. |

|

|

|

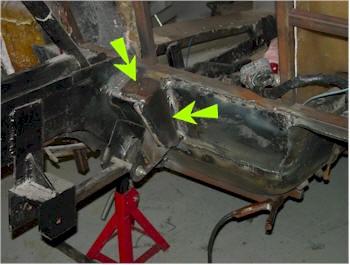

We capped the old cross-member with

1/4" plate steel |

We did this on both sides |

|

|

|

We then beefed up the bottom area

support with 1/4" plate |

The extra steel provided a strong

support area for the 2" .95 steel tube. We bend it to contour

the gas tank. |

|

|

|

Note the extra side support that ties

in the original cross-member location. |

We cleaned up some of the other holes

with 1/8" steel. |

|

|

|

While we worked on the support we sent

out the cradle to be powder coated and the transmission mount chrome

plated. |

The engine installed on the freshly

coated cradle. |

|

|

|

We added an additional support bracket

before we had it coated. This will tie into a future support

to help minimize the V8's twist and torque. |

Shot of the rear with the Chrome

transmission support. The picture does not due this justice.

It is very sharp. |

|

|

|

We measured for the axles and had a

local Clutch and Joint (Dayton Clutch and Joint) mate a new Porsche

and Fiero axles into one. ours measured 26" however we also

have a +1 inch wide track rear end. We measured within 1/8"

tolerance. |

Another view of the axles |

|

|

|

Ok we removed the water pump and are

having a new inlet machined in it. More on that later. |

View from the top . |

| |

|

| |

|

| |

|

| |

|

| |

|

| |

|

| |

|

| |

|

| |

|

| |

|

| |

|

| |

|

| |

|

| |

|

| |

|

| |

|