|

|

| These are the Mirrors that came with the D&R

kit. There is not any nice locators for the motors from the Fiero

like some other kits however the fiberglass is very good quality. Since

I want it to look original and I wanted the detail of "break-away"

mirrors I decided to attempt to convert the one piece mirrors into two

piece. |

|

|

| |

|

|

|

| This is the original Fiero

mirrors and motor assembly. Rather than trying to snap the mirror

on and off I removed the glass from each mirror. This reveals

three screw holes used during the manufactures assembly. At the

factory they mounted the glass in the mirrors last by gluing it on. This

is what I plan on doing do minimize the risk of damaging the pivots. |

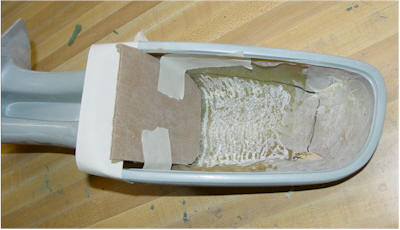

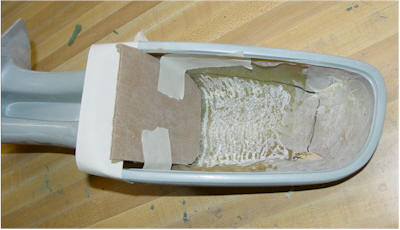

Since the Mirror has no

mounting location I filled the bottom of the Mirror bucket with

Duraglass |

|

|

| I then set the Original

assembly with the metal mounting stand with the mirrors at the middle

settings "Neutral" Meaning they have room to go up and down

and left and right. |

After the Duraglass setup

I unscrewed the mirror motor assembly from the stand leaving a perfect

mounting location. |

|

|

| I reinforced the mounting

brackets with fiberglass |

|

|

|

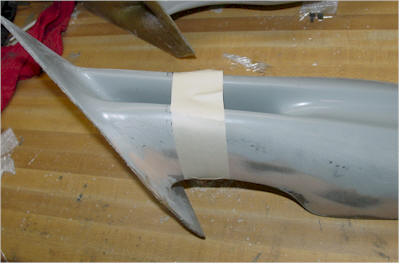

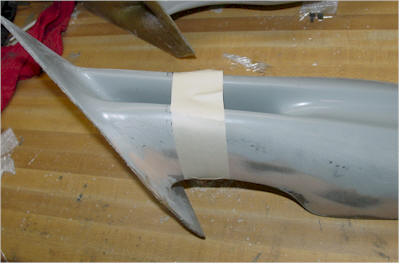

| After closely looking at an

original I marked a perfect line around the mirrors so that I could

separate it with a straight cut. |

I followed my lines and

used a metal hacksaw blade to make a flush cut |

|

|

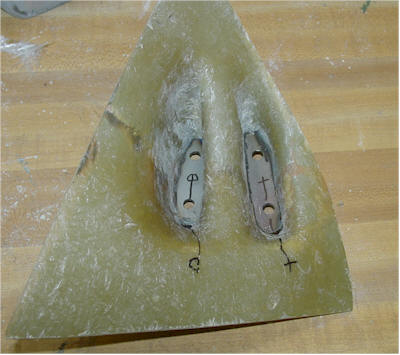

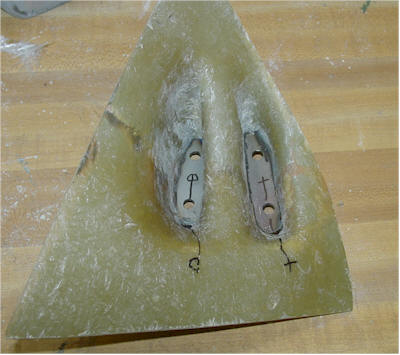

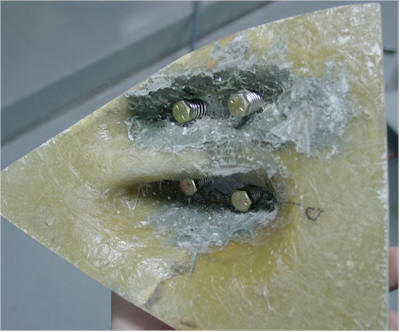

| I then cut 1/8" steel

plates to reinforce the mounting points |

the is the other side you

can see the metal is recessed about a 1/4" |

|

|

| I filled in the area with

Duraglass. To make it stronger I chopped up some fiberglass and

mixed it in. I then drilled out the holes matching the holes I

made in the steel. |

I fitted four 1/4" bolts

and placed a spring between the bolt and the inside of the mount.

This will allow for the flex the break-away mirror need |

|

|

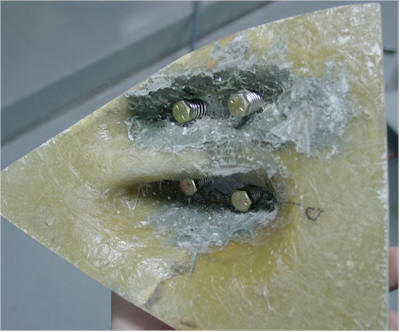

| I secured the bolts with a

temporary nut |

I then cut two more1/8"

steel plates just enough to connect two more permanent nuts. The 2

I placed on first simply provide me with the 1/4" spacing I will need

for the other side of the mirror. I tacked welded the nuts to the

plate. Since these nuts will be glassed in I did not want the

chance of them breaking free in the fiberglass later thus being useless. |

|

|

| I then placed Duraglass

inside the other side of the mirror and then pressed the two pieces

together. After it hardened I unbolted the mirror. Filled in

the area with Duraglass leaving the two bolt holes. Before I did

this I drilled a larger hole for the wires to feed through. |

I then bolted the

assembly together |

|

|

| Depending on how much I

tightened the bolts on the springs determines the amount of "flex" the

mirror has. Because there are 4 bolts there is no need for any

guides. |

I still have to finish off

the mirrors and place a plastic bushing between the pieces however you

can see the flex of the joint in this picture. |

|

|

| Finished and ready for

primer |

|

|

|

| All "primered" up and with

the plastic cushions installed |

The plastic cushions is

simply a piece to black ABS plastic cut, sanded & polished |

|

|

| Looks pretty nice if you

ask me |

You can see the flex the

assembly has now |

|

|

| I can vary the flex by

either using softer or tighter springs and how much I tighten the

screws. |

On final assembly I'll use

lock tight to ensure they do not come loose after I do the final

adjustment |

| |

|

| I have included some close-up images

of the Mirror of a real car |

|

|

|

|

|

|

|

|

|

| |

|

| |

|